The first type of parquet we will discuss is solid wood parquet, which is

produced by using hard and durable wood, processed as a single piece at high

temperatures. Since there is no direct intervention in the material structure,

it preserves its natural qualities and appearance. The tongue-and-groove part

on the solid wood parquet, with a thickness ranging from 16 to 22 mm,

facilitates assembly during the installation phase. The application stages of

solid wood parquet include the primer applied to the floor, followed by parquet

installation, and then a sanding process called leveling after a certain

period, followed by optional polishing. Due to its natural properties, solid

wood parquet has a porous structure and is sensitive to moisture. The cost is

higher compared to other types of flooring due to being produced from a single

piece of wood and the challenges in the manufacturing process.

Laminate flooring panels are created by subjecting by-products of wood

and materials such as sawdust to high pressure with special adhesive materials.

The desired color and pattern are printed on paper, which is then impregnated

with resin on this panel. For scratch and impact resistance, it is covered with

a cellulose film layer. Underneath the flooring, there is a melamine coating

applied to protect against moisture. The click system makes the installation of

laminate flooring easy, using a floating system. Some products can also be

applied with an adhesive system. Laminate flooring is more cost-effective

compared to other types of parquet, does not require paint and polish, and has

high resistance to moisture. However, since it is not a natural material, it

lacks air permeability and may have disadvantages in terms of health.

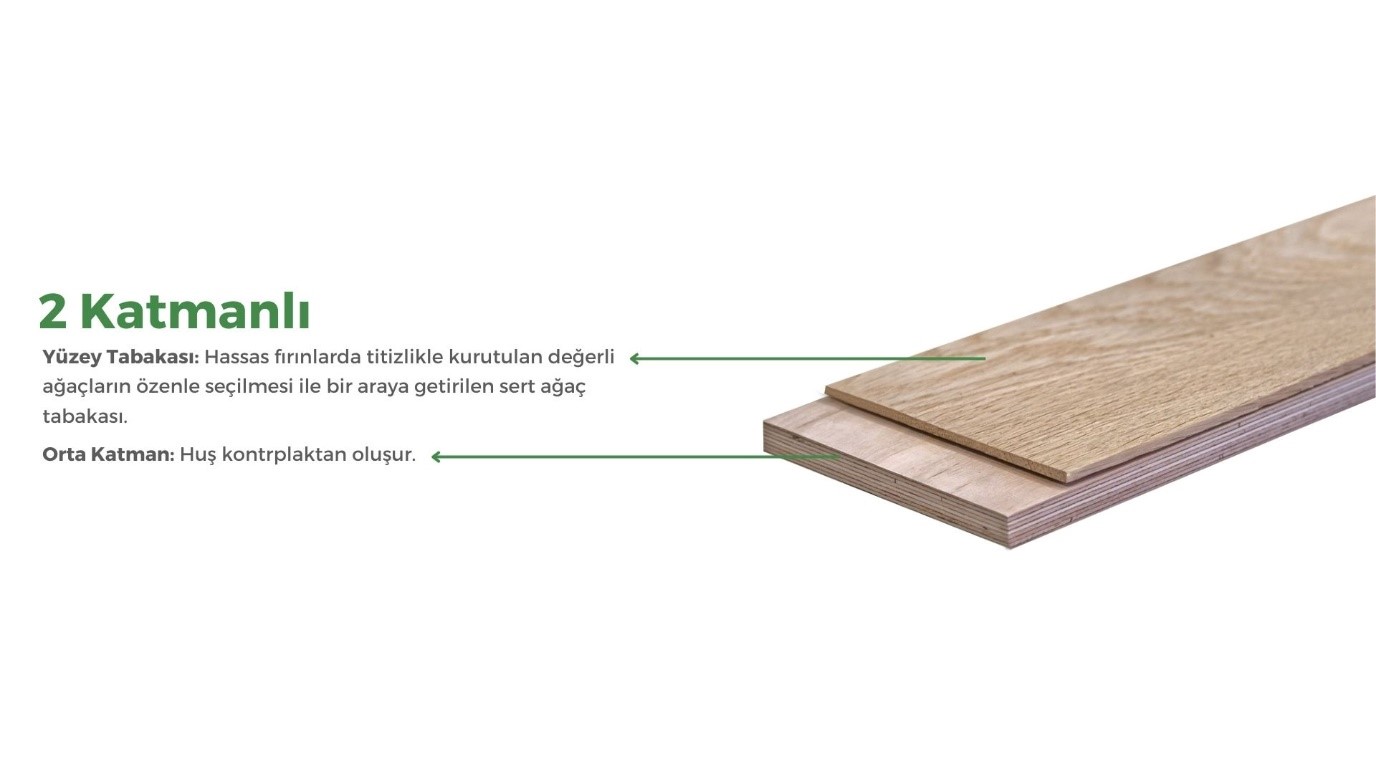

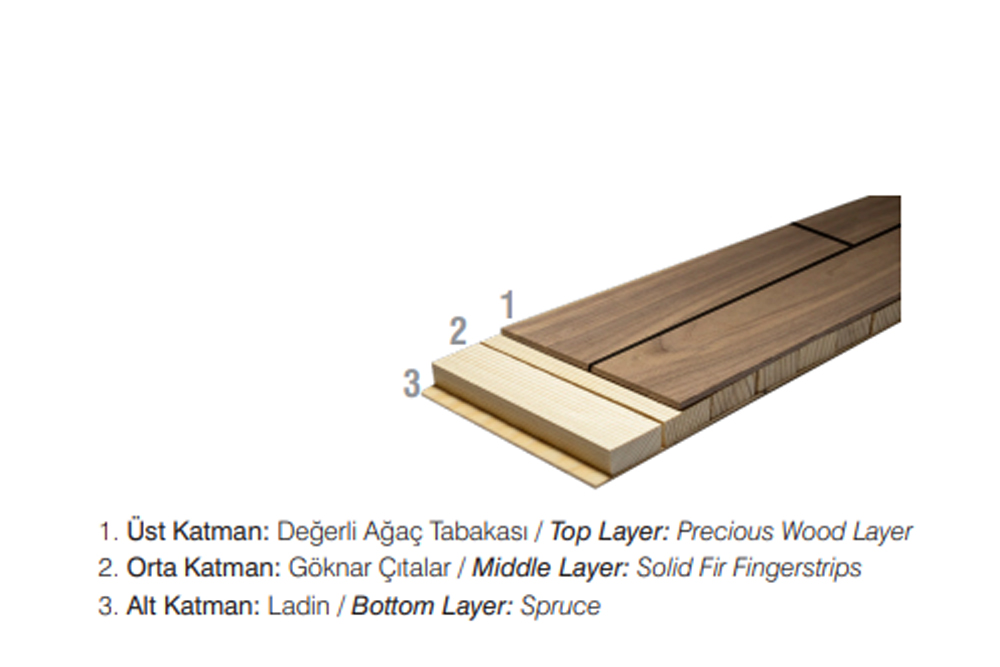

Engineered wood

flooring is produced by subjecting two or three layers of wood material to high

heat and pressure compression. While a lower-quality type of wood or plywood is

used in the lower layers, the upper layer contains the main material of the

flooring, which is the wood itself. Due to the use of natural wood in the upper

layer, it has a similar porous structure to solid wood parquet and possesses

breathability.

Attention is paid to the moisture range of the floor to be installed, and the floor is covered with an underlayment. Then, the flooring is assembled by interlocking through the tongue-and-groove parts. Although this system is generally referred to as a floating system, engineered wood floorings applied with adhesive are also available. For example, engineered wood produced with two layers are more flexible compared to those with three layers, and therefore, they are recommended to be glued for use in areas with uneven surfaces. Engineered wood floorings offered with a polished finish do not require any correction or additional polishing during installation.

Potential

deformations due to moisture, given the engineered wood floorings' similar

porous structure to solid wood parquet, can be addressed through a leveling

process. Situations requiring repair can be resolved quickly and at a low cost.

Engineered wood floorings are more cost-effective compared to solid wood

parquet due to their ease of processing and production. On the other hand,

considering their natural structure, they present a healthier alternative

compared to laminate flooring.

Engineered wood flooring is one of the most commonly used materials for floor coverings. Its long-lasting use, durable structure, stylish and timeless appearance, as well as its natural qualities, contribute to the widespread preference for engineered wood. In the selection of engineered wood flooring, the thickness of the boards used is a crucial consideration.

The thickness of

the flooring is a quality that holds importance in terms of durability. Factors

such as the current condition of the floor, the presence of insulation, the

purpose of the space, and the frequency of use influence the choice of

different thicknesses for engineered wood flooring. When determining the

thickness of the flooring, not only the characteristics of the engineered wood

but also the areas where it will be used, the current state of the floor, and

insulation needs must be taken into account as primary criteria.

In engineered wood

flooring, a total thickness of 12-20 mm is considered acceptable, with the top

layer thickness being 3-6 mm. The thickness of the top layer directly affects

the quality of the product. Opting for thinner and cheaper engineered wood

flooring may result in poor quality and a short-lived user experience. This is

because engineered wood flooring with a thin top layer will wear away over

time, rendering it non-functional in the long run. The thicker the flooring,

the stronger the profile durability, providing higher impact resistance and

wear resistance. These features are crucial for protecting the floor against

daily use, heavy furniture, and areas with high foot traffic. Therefore, paying

attention to the thickness of the top layer of wood is critical when choosing

long-lasting engineered wood flooring.

In engineered wood

flooring, the top layer plays a crucial role in achieving an aesthetic

appearance. A thicker top layer allows for the creation of more intricate

patterns and effective wood textures on the floor. This enables the floor to

more effectively reflect the natural wood feel, contributing to a more

aesthetic look.

The thickness factor also has an impact on sound insulation. Thicker enginered wood flooring absorbs sounds from below, making the space quieter. Additionally, it reduces footstep noises, providing a comfortable user experience. On the other hand, if there are minor flaws in the subfloor, thicker wood covers and corrects them, offering a smooth surface appearance.

Ultimately, thickness is crucial in many aspects when choosing engineered wood flooring and is critical for long-term performance. Thicker engineered wood options may be more costly, but considering their lifespan and aesthetic advantages, especially in high-traffic areas like kitchens or living rooms, they will help you maintain a beautiful and durable floor for many years.

https://www.wordofmouthfloors.com/blogs/flooring/the-ultimate-guide-for-laminate-flooring

https://cesmimarlik.com/parke-cesitleri-nelerdir-laminant-parke-ve-lamine-parke-nedir/